For metal fabrication, woodworking, automotive, construction, electronics manufacturing, and jewelry making industries abrasive discs have proven to be ultimate tools. Discs that have cutting, grinding and polishing edges are made for these industries to ensure that the finished products are up to whatever the required standards are.

Recognizing Abrasive Disc Types

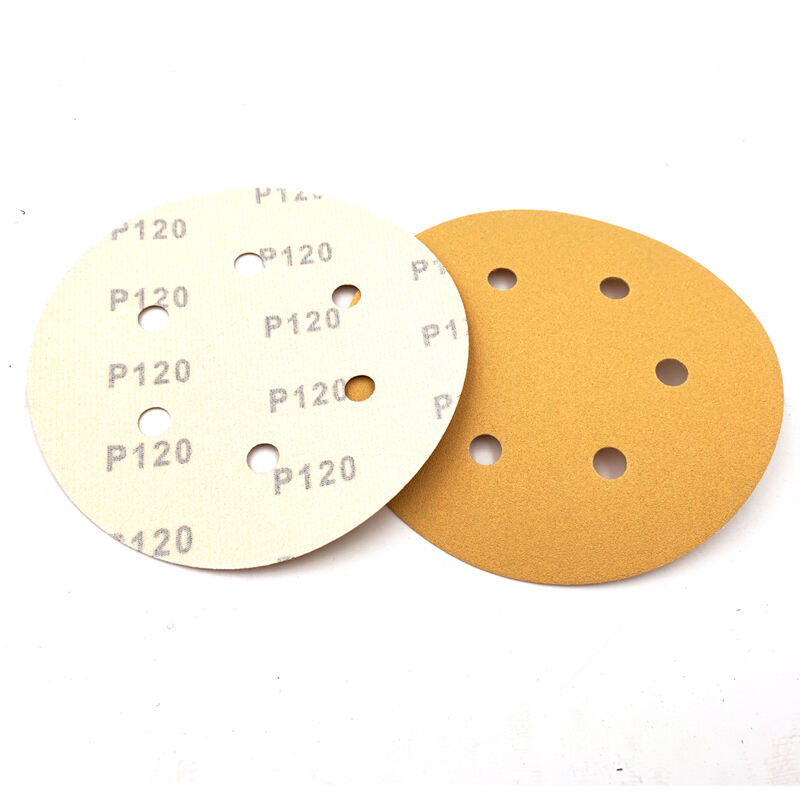

Due to very specific functions, abrasive discs come in various shapes and sizes, each devoted to one process or the other. Unlike the rest which are able to perform heavier demanding tasks, work with a ceramic flap disc, while other ceramic disposable pads will work great for polishing. Due to their orange color, strip and clean discs are able to work with Velcro backed, non woven pads enabling easy handling and of polishing on target sites.

Correctly Choosing an Abrasive Disc

Using the right abrasive disc is essential to prevent losses and maximize results from close to all jobs done. In simpler terms, it is important to think it through about the abrasive material to be worked with, the job type, be it cutting, grinding or polishing and the finishing level. Having technical documentation or talking to experts of this area can solve a problem as well.

Appropriate Usage and Care

For you to be able to derive maximum satisfaction from abrasive discs, it is essential to utilize them in the proper way and to also uphold proper maintenance practices. This includes adhering to the manufacturer’s speed and pressure limitations, checking the discs for deterioration and damage on a regular basis, and keeping them in a dry cool place when not in use.

Safety Measures

When working with abrasive discs, you need to put safety first. Use suitable personal protective equipment like safety goggles, gloves, and soundproof earmuffs. Check the condition of the machine with the abrasive disc fitted before swinging into action.

Personalization and Advertising

If you are a business that wants to enrich your customers with something special, consider personalization services. Among the companies providing, which offer OEM and ODM services, which means customers will label their abrasive discs and make them different as per their desires.

Users are making sure that the abrasive discs they are using are able to accomplish their objectives in the most efficient way possible by adhering to the best practices provided. No matter if it is the selection of an appropriate disc type, its usage, and maintenance, or safety aspects, it can be assured every project is done to the best expectation. As for a company that wishes to be in good hands in the field of abrasives, FANTECH is prepared with quality and professionalism to be successful.

Hot News

Hot News2024-07-18

2024-07-18

2024-07-05