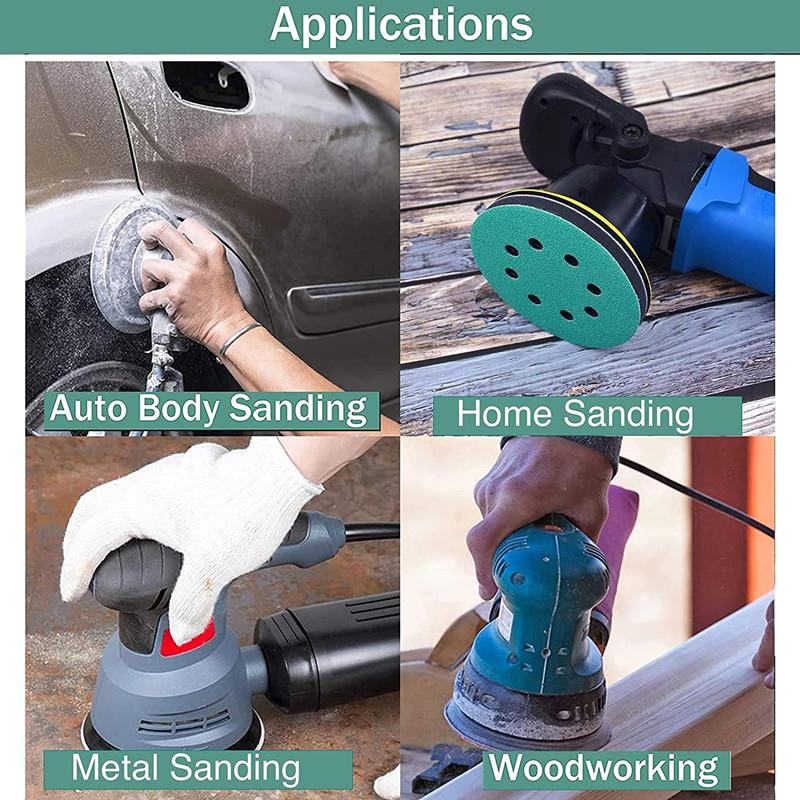

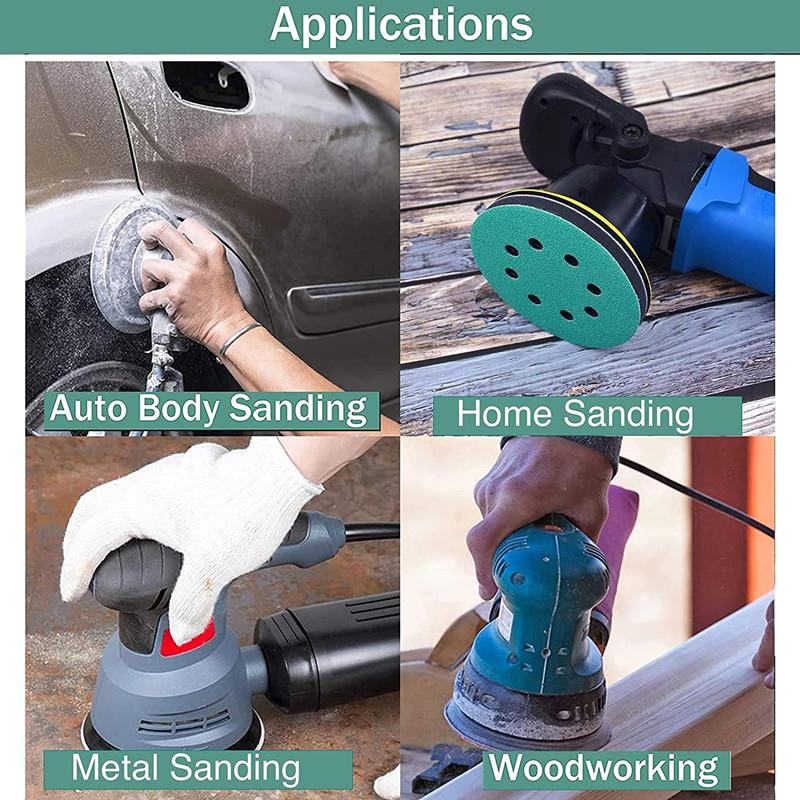

Application:

Circular backed flock sandpaper, as an important member in the field of grinding materials, is specifically designed for various fine grinding and polishing tasks. With its unique circular shape and backed flock design, it demonstrates excellent performance in surface treatment of various materials. It is widely used in industries such as furniture manufacturing, automotive maintenance, metal processing, and handicraft production, playing a crucial role in improving the surface quality of products.

-

Abrasive Layer:

-

Material: High-quality abrasives such as silicon carbide (SiC) and aluminum oxide (Al₂O₃) are used. Silicon carbide abrasives have high hardness and strong wear resistance, and are suitable for rough and semi-fine grinding of materials with high hardness, such as metals and glass. Aluminum oxide abrasives have good toughness and can maintain good cutting performance during the grinding process. They are often used for fine grinding of softer materials like wood and plastics, as well as for fine grinding of metals.

-

Grit Distribution: Ranging from coarse grits like 40# and 60# for quickly removing a large amount of material to fine grits like 1000#, 2000# and even finer, it can achieve ultra-fine polishing to meet the requirements of different grinding stages. The grits are evenly distributed on the surface of the sandpaper to ensure the consistency of the grinding effect.

-

Bonding Layer:

-

Performance: High-strength and wear-resistant adhesives are used to firmly bond the abrasives to the substrate. This ensures that the abrasives do not fall off during high-speed grinding and long-term use, maintaining the normal service life of the sandpaper. At the same time, it ensures a tight bond between the abrasives and the substrate, transmitting the grinding force and improving the grinding efficiency.

-

Substrate:

-

Material: High-quality paper or polyester film is selected as the substrate material. The paper substrate has good flexibility and is suitable for grinding curved and irregular surfaces, and can conform to complex-shaped workpieces. The polyester film substrate has high strength and tear resistance, and has good stability when used on high-speed grinding equipment. It is suitable for planar and large-area grinding operations.

-

Backed Flock Layer:

-

Structure and Function: The backed flock layer is composed of soft and elastic fluff, which is adhered to the back of the sandpaper through a special process. The length and density of the fluff are carefully designed to closely fit the adhesive backing plate of the grinding equipment, providing a stable adsorption force to prevent the sandpaper from shifting during the grinding process, ensuring the safe and precise operation of grinding. At the same time, the elasticity of the backed flock can buffer the impact force during grinding, reducing damage to the surface of the workpiece and making the grinding effect more uniform and delicate.

-

Efficient Grinding: With high-quality abrasives and a reasonable grit distribution, the sandpaper has strong cutting power, quickly removes surface defects and rough layers of the workpiece, improves the grinding efficiency, shortens the processing time, and reduces production costs. For example, in furniture manufacturing, the coarse-grit circular backed flock sandpaper can quickly smooth out the knots and burrs on the surface of the wood, laying the foundation for subsequent fine grinding.

-

Fine Polishing: The fine-grit sandpaper, combined with the buffering of the backed flock, can achieve a mirror-level polishing effect, creating a smooth and shiny texture on the surface of metals and handicrafts, enhancing the appearance quality and added value of the products. For example, in automotive maintenance, the grinding and polishing of the body after local paint repair can make the repaired part perfectly blend with the original car paint surface.

-

Good Conformability: The circular design and the elasticity of the backed flock enable it to closely conform to the surfaces of various workpieces, including flat, curved, and concave-convex surfaces, without any grinding dead angles, ensuring a consistent overall grinding effect. When grinding irregularly shaped handicrafts, it can flexibly adapt to complex shapes to ensure that every detail is properly processed.

-

Long Service Life: The sturdy bonding layer and high-quality substrate can resist wear and tear during the grinding process, extending the service life cycle of the sandpaper, reducing the frequency of sandpaper replacement, and improving production continuity. In high-intensity grinding operations in metal processing, it can still maintain good performance and reduce the cost of consumables.

-

Safe and Convenient: The close adsorption of the backed flock to the equipment prevents the sandpaper from flying off, ensuring the safety of the operators. At the same time, the sandpaper is easy to replace and can be quickly installed on various grinding equipment with adhesive backing plates, such as electric grinders and pneumatic grinders, improving work convenience.

-

Furniture Manufacturing: Conduct rough grinding, fine grinding, and polishing on solid wood and panel furniture, treating the pits and burrs on the wood surface to make the furniture surface smooth and flat, and ensuring an even color and delicate texture after painting.

-

Automotive Maintenance: Used for grinding and polishing the body paint surface after repair to eliminate paint repair marks and restore the original luster of the body; grind and refurbish metal and plastic parts such as car wheels and interior parts.

-

Metal Processing: In the manufacturing of metal parts and machining processes, conduct rust removal, removal of oxide scale, grinding of weld seams, fine grinding, and polishing on the metal surface to improve the surface finish and precision of the metal.

-

Handicraft Production: For handicrafts made of ceramics, glass, jade, wood, etc., conduct fine grinding and polishing to showcase the unique texture and luster of the handicrafts and enhance their artistic value.

-

Electronics and Electrical Appliances: Grind the outer casings and internal metal structural parts of electronic devices to meet the requirements of appearance decoration and assembly precision, such as the grinding of mobile phone and computer casings.