- Overview

- Related Products

-

Composition

- Abrasive: Fused alumina-zirconia is the main abrasive, which is produced by smelting high-purity zirconium oxide and aluminum oxide at a temperature above 2,500°C through the pouring furnace and plate cooling method. It has the characteristics of high hardness, strong toughness, and good grinding performance. The crystal size is relatively fine, generally showing a gray-brown color. The main mineral phases are α - Al₂O₃ and the eutectic formed by Al₂O₃ - ZrO₂, the secondary crystal phase is baddeleyite, and there is also a small amount of glass phase. According to the content of ZrO₂, common types include 25 fused alumina-zirconia (ZrO₂ 25%) and 40 fused alumina-zirconia (ZrO₂ 40%). The self-sharpening property of the 40% ZrO₂ content fused alumina-zirconia is better than that of the 25% content, and it is more suitable for making coated abrasives, etc.

- Adhesive: High-performance adhesives such as resin are usually used, which can firmly bond the fused alumina-zirconia abrasive grains to the abrasive belt substrate, ensuring that the abrasive grains do not easily fall off during the grinding process. At the same time, it has good temperature resistance and wear resistance.

- Abrasive Belt Substrate: The cloth base is made of materials such as pure polyester, which has the characteristics of high strength and good toughness. It can withstand the tension and friction during the grinding process and adapt to various grinding working conditions, such as heavy-duty grinding.

-

Product Specifications

- Grit: Common grits include 40 - 120 mesh, etc. Different grits are suitable for different processing stages and surface precision requirements. Coarse grits such as 40 mesh and 60 mesh have strong grinding force and are used for quickly removing materials and rough machining. Fine grits such as 100 mesh and 120 mesh are used for semi-finishing and finishing, and can obtain a better surface finish.

- Size: For example, there is a specification with a perimeter of 2,100 mm and a width of 50 mm. In addition, there are various different lengths and widths available to meet the needs of different abrasive belt grinding equipment.

-

Performance Advantages

- Good Self-sharpening Property: During the grinding process, due to the large toughness value of the fused alumina-zirconia abrasive grains, new cutting edges can be continuously generated, maintaining the sharpness of the abrasive grains. Thus, it can effectively carry out cutting continuously, improving the grinding efficiency and increasing the surface finish of the ground workpiece.

- High Wear Resistance: Fused alumina-zirconia itself has good wear resistance. Coupled with high-quality adhesives and substrates, the overall abrasive belt is wear-resistant and has a long service life, which can reduce the use cost.

- Strong Heat Resistance: It can withstand a relatively high grinding temperature and is not easy to cause the abrasive grains to fall off or the substrate to be damaged due to heat generation during the grinding process, especially suitable for grinding heat-resistant alloy steels and other materials.

- Self-lubricating Effect: Some fused alumina-zirconia abrasive belts with a third coating have a self-lubricating property, which can reduce the temperature in the grinding zone, form cold grinding, reduce the possibility of workpiece burning, and improve the processing quality.

-

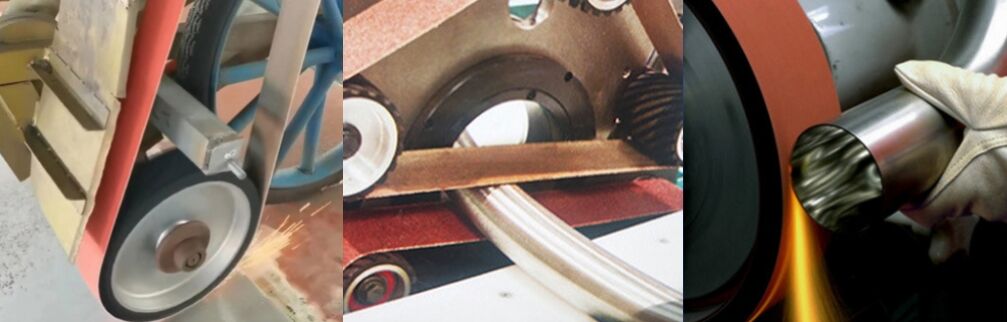

Application Scope

- Metal Processing: It is mainly used for heavy-duty grinding, especially suitable for grinding heat-resistant alloy steels, titanium alloys, and austenitic stainless steels. It can also be used for the grinding of precision castings to remove burrs, flashings, and runners, etc. In industries such as kitchenware manufacturing, valve fitting manufacturing, and knife and scissors manufacturing, it is used for the grinding and polishing of various metal parts.

- Other Fields: In the golf industry, it is used for grinding the gates of the golf club heads and the golf club hairs, etc.

-

Usage Precautions

- Storage Conditions: It should be stored in a dry and ventilated environment, avoiding moisture and direct sunlight to prevent the deformation of the abrasive belt substrate and the rusting of the abrasive grains.

- Installation Requirements: When installing, ensure that the abrasive belt is correctly installed on the grinding equipment, and the tension is moderate. Avoid excessive tightness or looseness, which may cause the abrasive belt to run off or break.

- Selection of Grinding Parameters: According to the workpiece material, hardness, and processing requirements, reasonably select grinding parameters such as grinding speed, feed rate, and grinding pressure to avoid excessive wear of the abrasive belt or poor processing quality due to inappropriate parameters.

- Requirements for Dry Grinding: Fused alumina-zirconia abrasive belts are mostly dry grinding abrasive belts. During the use process, they should avoid contact with water, otherwise, it will affect the grinding performance and the service life of the abrasive belt. If a large amount of dust is generated during the grinding process, the corresponding dust collection equipment should be equipped to keep the working environment clean.

-

Market Brands: Well-known brands in the market include 3M from the United States, 野牛 (Ushi) from Japan, Deerfos from South Korea, Norton, etc. For example, the PZ533 series of fused alumina-zirconia abrasive belts of Deerfos from South Korea uses a strong polyester cloth base and performs excellently in grinding super-hard and super-tough stainless steels such as types 304 and 316 and alloy steels, and is widely used in multiple industries.

请将“磨料的粒度和形状会影响砂带的磨削效果。较细的粒度适用于精细加工,较粗的粒度适用于粗加工。常见的磨料形状有圆形、菱形和三角形等。”翻译成英文。

你还知道哪些砂带的类型?

你可以提供一些关于砂带使用和保养的建议吗?