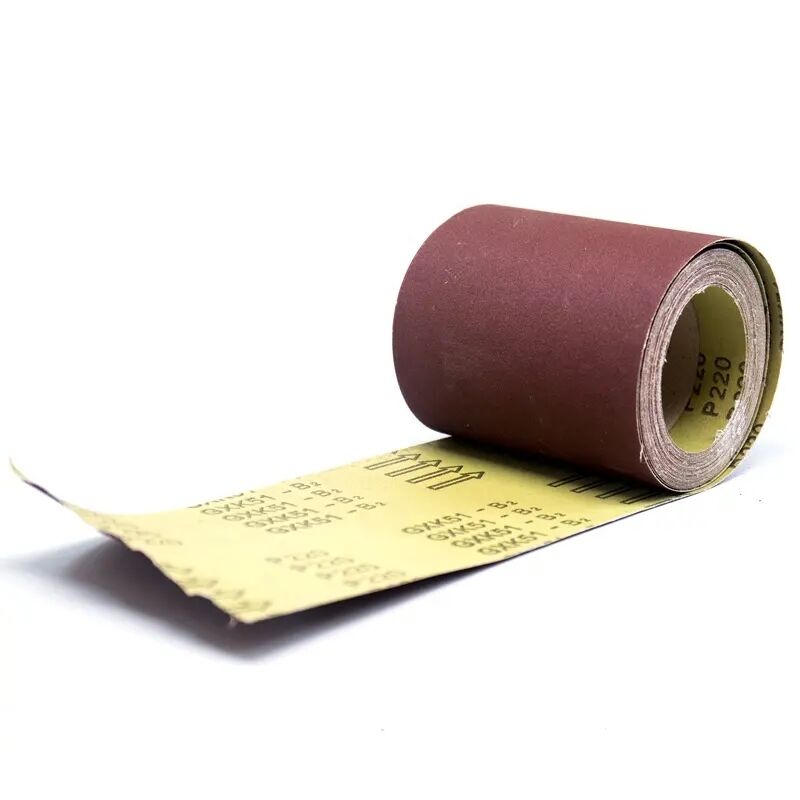

Abrasive belts are useful for sanding and finishing countless tasks in different industries. Essentially, abrasive belts consist of a flexed backing material that’s been coated with a fine layer of abrasive grains, enabling it to remove materials from a workpiece. Through FANTECH, the abrasive belts sold are of almost all types and they cater to the needs of customers in an adequate manner.

Finding the Appropriate Non-Woven Abrasive Belt

In order to get the ideal performance it is important to choose the right abrasive belt. Start by assessing the material that needs to be worked on, the type of job (coarse grinding or fine finishing) and the end result, that is desired. The abrasive belts that we sell differ in grit, which includes aluminum oxide and silicon carbide, and which have various uses.

Work Precautions

Abreast of using abrasive belts, pertinently take note of the work spars and location as well. It should be noted that dust is easily swallowed regardless of how easy or hard it might be and for this reason ensure to wear protective equipment like glasses, gloves, and a face mask as it stops dust from flying around and improves the working conditions.

What Should Be Done Before Using Abrasive Belts

A few safety measures should be followed at all times such as keeping the surrounding work area well ventilated and tidy. Make sure to wear the right safety equipment before working on any project, including but not limited to gloves, glasses, or a mask. Not only does this protect you from unwanted debris being scattered but it also assists in keeping everything clean.

Operating the Abrasive Belt Sander

The first thing to remember when using an abrasive belt sander is to read the guidelines given by the manufacturer. So, tighten the belt so it does not slip, and wear it uniformly. Switch on the machine at a minimum RPM and increase it whenever required. When sanding, apply consistent force on the work and refrain from sudden jerks that would damage the belt or the machine.

Maintaining Abrasive Belts

Taking due care of the equipment will always make it last longer. Always inspect the belt for damage or wear after use. Remove dust and other deposits off the belt using a soft brush or compressed air. Store the sanding belts flat or rolled up, in a dry place distant from direct light to avoid contour deformation or breakdown.

Troubleshooting Common Issues

If you see signs of the belt slipping or uneven wearing of the belt, it could be that the belt is not under adequate tension or the abrasive surface is too worn out. So, either increase the clamp tension or change the belt. If the belt is not running in the correct position, check if the sander's rollers are in the right position, if not make the necessary changes.

Boosting Productivity with FANTECH Abrasive Belts

FANTECH knows that efficiency is a critical thing in an industrial setting. Our abrasive belts are designed to meet the ‘high performance’ standard so that you understand the worth of your investment. Follow these usage and maintenance tips and make the most out of your abrasive belts’ life and efficiency.

Hot News

Hot News2024-07-18

2024-07-18

2024-07-05