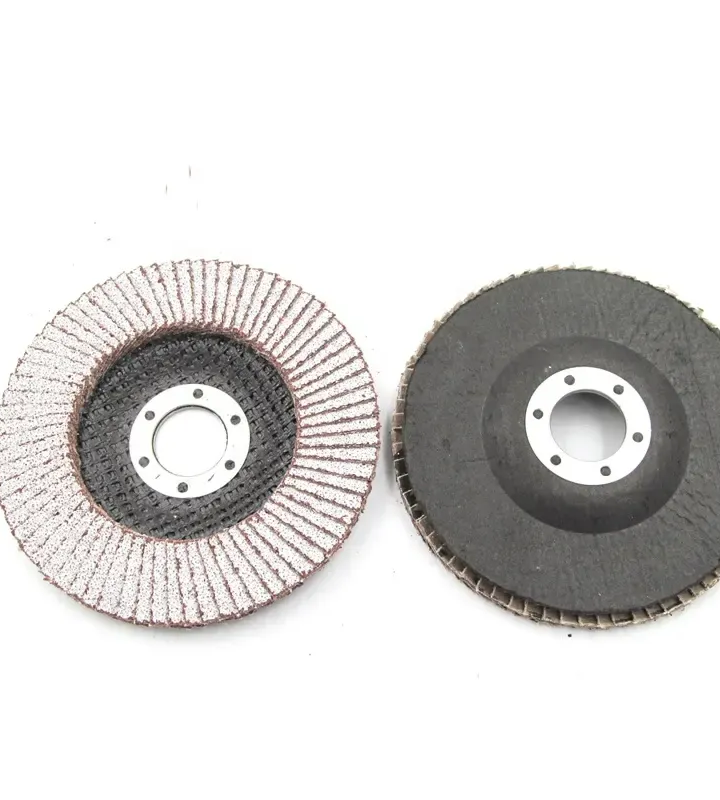

FANTECH Flap Wheel for Long and Effective Surface Finishing

The FANTECH flap wheel is designed so well that it is able to perform abrasively on different surfaces such as aluminum and wood. Thanks to the innovative shape of the wheel, cutting action is maintained consistently throughout the life of the wheel regardless of how many times a surface has been worn out. No matter if you need to grind, polish or simply finish the top surfaces before using other treatments, FANTECH flap wheels guarantees a neat and uniform surface without any rough edges. This is partly due to FANTECH flap wheels having a high build quality and abrasive material making them suitable for both professional and home users who want efficiency and accuracy from their tools. The wear and tear of the flapper design presents an advantage to the operator in that it avoids overheating of the workpiece while extending the life of the wheel. Users of FANTECH flap wheels do not have to worry about the availability of the machines, as the company has made it possible for their flap wheels to fit various machines commonly used in the automotive, building and metal working industries. If you want to get rid of burrs left after welding or simply wish to remove paint or rust, the FANTECH flap wheel will be an excellent assistant at a finishing stage.

FANTECH: Flap wheels perfectly engineered for maximum efficacious stock removal

Each flap wheel design integrates efficiency as a consideration and FANTECH is no exception. This is because these are performed to the optimum making FANTECH flap wheels ideal to users who wish to work with speed and accuracy. FANTECH flap wheels are very aggressive in their intended use with respect to cutting hence surface preparation like rust, lacquer, and surface dirt removal is a quick task due to the abrasive proficiency. What makes all the difference for them is mainly the quality of the abrasive materials used and the flap arrangement design. Every wear of the wheel exposes a new shredding edge as each flap is covered down. There is high performance with this approach and it also minimizes the frequency of replacement of cut and worn out tools, therefore lowering the operational cost. Since FANTECH accommodates the provision of efficient and quality advantage tools, their flap wheels are suited for both the neglect activities of huge industries and also activities that require precision. If you need reliable results in a short time whether it is for surface preparation before painting or for running over welded joints, FANTECH flap wheels come through.

FANTECH Flap Wheels: Allow Multi-Material Uses Terrific Prospective

The greatest advantage of FANTECH flap wheels is perhaps their great adaptability. Designed to work on several materials, from metals such as stainless steel and aluminum to softer materials such as wood and plastic, FANTECH flap wheels are an essential accessory in all workshops. This also makes it very suitable for professionals who are faced with the challenge of getting a single product that able to perform different tasks without changing the tools. There’s indeed Android App Development in FANTECH and that’s them selling it in the fact that they do possess variations of flap wheels that can go in various angles of operation from doing the aggressive side of removal process to the fine polishing aspect. About each flap is strengthened for strength without losing the bendy capability to accommodate varying geometrical contours. FANTECH also makes sure that their flap wheels are developed in more than just one grit, so that the user will be able to select the appropriate abrasive grit for the required surface. In metalworking, woodworking and even plastics, FANTECH flap wheels are sufficient to cope with various tasks due to the necessary cross-functionality.

FANTECH: Flap Wheels Designed for the Users’ Comfort and Control

At FANTECH, comfort and control of the product within the user’s confines is the primary focus in the product design and the case is the same for their flap wheels. Users of FANTECH flap wheels which are ergonomically designed can exert more control to complete operation and this in turn helps reduce hand fatigue and increases productivity. This thus bring them to be Ideally used as industrial products for long working hours or even used for focused work that demands exactitude. FANTECH flap wheels features that help in generating low vibrations in turn enhances the quality of the grinding by making it more pleasant. Flat flap design also solves the problem this helps in distributing pressure more evenly over the whole surface and lessens the occurrence of unwanted injury of the workpiece. Because of FANTECH’s focus on developing user friendly products, their flap wheels are even easy for lesser experienced operators to deploy. By focussing on comfort and control over the efforts of FANTECH, it is not only the effectiveness of the flap wheels that gets highlighted, but the shear delight of using it as well which makes it ideal for both professional and amateur users.

There are applications where heavy wear and tear is to be expected and that’s where the FANTECH flap wheels come into play. These wheels are specially made to last, using quality tellos to ensure that the wheels endure even the harshest of conditions. FANTECH flap wheels are ideal for grinding, polishing, and de-burring applications that will require continuous surface grinding tools. Most grinding wheels are usually destroyed after many uses, but because of the new innovative multi-layered flap construction used in FANTECH, the products last longer. Each flap wears constantly in a balanced manner so that consistent working conditions are maintained over a prolonged time, and thus these could be recommended for metal work fabrication, automobile repair, and buildings construction. FANTECH flap wheels not only withstand the rigors of the tasks for more time but also can be used on hard as well as soft materials. With FANTECH, the users are sure to be getting a product that integrates durability, strength, and versatility - characteristics that make any tool professional grade.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Yes, FANTECH flap wheels are designed for versatility, making them suitable for both grinding and polishing, providing a smooth and consistent finish.

For fine polishing, we recommend using a finer grit size, such as 120 or higher, depending on the level of finish you require.

FANTECH flap wheels perform exceptionally well on stainless steel, offering efficient material removal while ensuring a smooth and scratch-free surface.

Absolutely, FANTECH flap wheels are built for durability, ensuring long-lasting performance even during continuous, heavy-duty industrial applications.

Yes, FANTECH flap wheels are flexible and designed to conform to irregular surfaces, providing a uniform finish without damaging the workpiece.