The most important consideration concerning power tools and accessories is safety, and FANTECH flap discs are manufactured in this regard. Our flap discs aim to avoid any such incidents while allowing the user to achieve the highest level of performance. All the discs have passed control over the safety of each product that allows one to be worry-free during working hours. The safe holding system in FANTECH flap discs prevents the slippage of the discs during use, hence enhancing quicker grinding processes and relieving the incidence of kickbacks. Moreover, the design of our discs reduces vibrations; this, in turn, increases comfort and accuracy when using the discs. Safety is something that we need to set aside when using FANTECH flap discs and concentrate more on the project. We think that good products cannot only work good but also cover the user’s safety and this is what culture of quality of the flap discs is all about making it a perfect choice for all your grinding operations.

FANTECH appreciates that how long a person can use a tool is utmost dependent on the level of comfort offered and this is the reason why the flap discs are made as per the user. Because of the sensitive material that FANTECH flap discs are made of, it is possible to operate them without getting tired even after several hours of grinding. Other benefits include improved ergonomic design through vibration reduction whilst the flap discs are in use. Such commitment to comfort does not compromise how well FANTECH flap discs tempt removal and surface finishing. FANTECH flap discs are just as effective in terms of material removal and surface finish however the additional advantage is that the operators can work for longer hours in more demanding operations without the discomfort usually caused by heavy grinding. If you are a metal fabricator or a DIY enthusiast who spends several hours during the day doing metal work or performing other related work, FANTECH guarantees you that you will remain comfortable regardless of the flap disc that we make.

At FANTECH, we realize that each project differs from the other and therefore we provide a variety of flap discs as per different requirements. FANTECH has flap discs for all the stages and phases of a project, from the rough grit flap discs which are heavy removal ones, to finer grits meant for finishing and polishing. Our product mix contains various types of flap materials such as zirconia and aluminum oxide designed for specific applications like sanding metals cutting wood or removing rust. Thanks to the customer orientation of FANECH, we strive to ensure that our products and their variants are modified with time to suit the changing demands of the professionals in the market. If it is a case of intense plying or disc grinding of the best, quality cuts in a very fast time frame that’s often required FANTEC comes to the rescue. Instead of offering general products that may not meet the needs of all the customers, we make sure that every customer receives a perfect product applicable for that project. This improves both the efficiency of work and the results achieved.

At FANTECH, it is safe to say, quality is of paramount importance. FANTECH flap discs are produced in compliance with precise and set guidelines which ensure that every product that carries our name satisfies our customers’ expectations. Primary use of high-quality abrasives and other materials is made in the construction of the flap discs so that they can work effectively in the performance of different tasks. Study processes at FANTECH are directed at the findings of each flap disc and they also result into the achievement of set functions under the defined conditions FANTECH Assurance processes on the quality of flap discs ensures that every flap disc can be relied on to produce the precise effects desired, be it grinding, deburring or polishing. comprimation organ at FANTECH assures that you shall be receiving the same level of control over true quality eliminating production of devices that cannot deliver according to FANTECH flap discs getting expected deliverables. FANTECH understands the tools for the professionals in various industries are much more than just effective. FANTECH is with you in every aspect as it strives to be among the leaders in every industry using its tools.

FANTECH flap discs leave no one in doubt when it comes to precision and operational performance. Each individual flap disc manufactured by FANTECH is subject to strict testing and design improvement to guarantee that a high level of precision is achieved during grinding and finishing processes. Flaps are made of adequate materials to ensure that accurate blade wear occurs uniformly over time thereby achieving accurate removal and surface finishing even after prolonged app of bladed structures. This uniform feature cuts across all FANTECH flap discs, serrated or non-serrated which explains the balanced performance across different flap type of discs. This attention to detail means that regardless of whether you are using the discs on metal, wood or composite materials, our discs provide finer finishes, good handling, and better results. FANTECH is specific in engineering and manufacturing flap discs such that with the right technique, users achieve polish levels that only professional level polishers can achieve; this makes flap discs a preferred tool for those in search of excellence in their tools.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

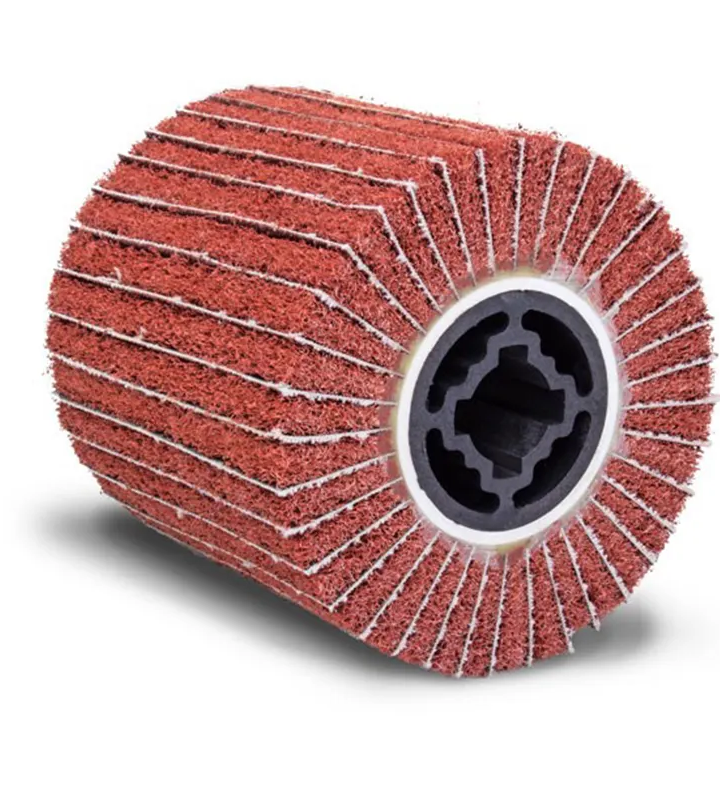

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Yes, FANTECH’s flap discs are suitable for both steel and stainless steel, providing efficient grinding and a smooth finish for both materials.

Absolutely, FANTECH offers flap discs in a wide range of grit sizes, ensuring that you can select the right one for aggressive grinding or fine surface finishing.

FANTECH flap discs are highly durable, designed to withstand continuous industrial use, reducing the need for frequent replacement and improving overall efficiency.

FANTECH flap discs use high-quality fiberglass backing, which offers excellent strength and durability, ensuring stability during high-speed grinding operations.