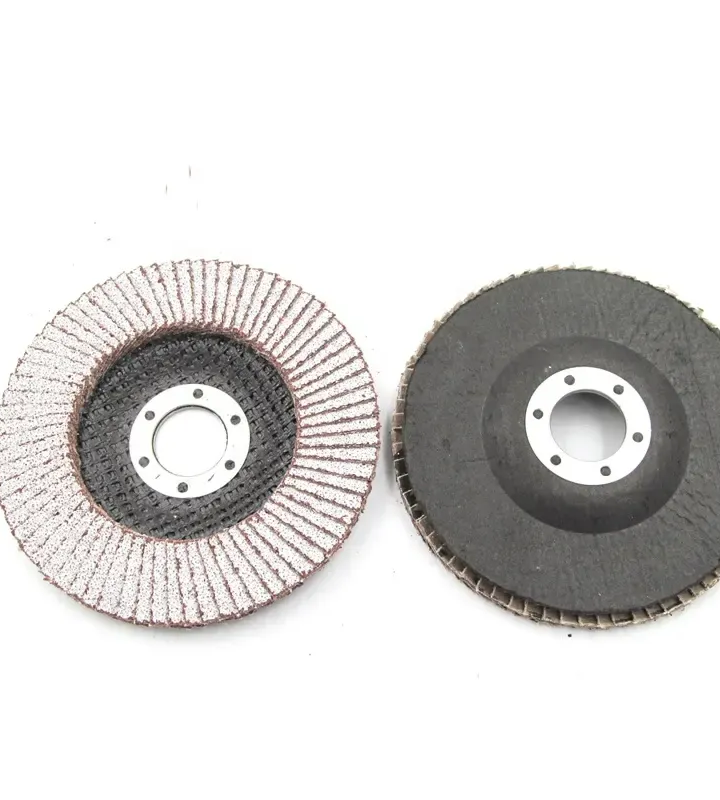

FANTECH Flexible Flap Wheel for Enhanced Workpiece Conformity The FANTECH flap wheel provides maximum flexibility and can be used in places where the tool needs to take the works piece form. This is quite handy when shaping operations are involved on a workpiece whose surface is not flat, where a grinding wheel will be so unnecessary. The unique flap design by FANTECH makes it easy for the wheel to adapt to the misaligned of shapes without compromising the functionality or quality of the finishing. Each of the low profile purpose plates has been designed so as to include layered abrasives and afford the continuous cutting action to advance flow from one area of the work-piece to another. Whichever it is sanding, blending or even polishing, FANTECH flap wheels provide the required adaptability to accomplish various tasks accurately and efficiently. Also, because FANTECH flap wheels undergo stringent quality control processes, each flap wheel is capable of being used on all kinds of materials from softwoods to hardened metals without ever breaking bulks. Especially useful characteristics are necessary for the ‘FANTECH flap wheel’ to scape surfaces that require blending or where there is a lot of detail.

FANTECH Flap Wheels: Allow Multi-Material Uses Terrific Prospective

The greatest advantage of FANTECH flap wheels is perhaps their great adaptability. Designed to work on several materials, from metals such as stainless steel and aluminum to softer materials such as wood and plastic, FANTECH flap wheels are an essential accessory in all workshops. This also makes it very suitable for professionals who are faced with the challenge of getting a single product that able to perform different tasks without changing the tools. There’s indeed Android App Development in FANTECH and that’s them selling it in the fact that they do possess variations of flap wheels that can go in various angles of operation from doing the aggressive side of removal process to the fine polishing aspect. About each flap is strengthened for strength without losing the bendy capability to accommodate varying geometrical contours. FANTECH also makes sure that their flap wheels are developed in more than just one grit, so that the user will be able to select the appropriate abrasive grit for the required surface. In metalworking, woodworking and even plastics, FANTECH flap wheels are sufficient to cope with various tasks due to the necessary cross-functionality.

There are applications where heavy wear and tear is to be expected and that’s where the FANTECH flap wheels come into play. These wheels are specially made to last, using quality tellos to ensure that the wheels endure even the harshest of conditions. FANTECH flap wheels are ideal for grinding, polishing, and de-burring applications that will require continuous surface grinding tools. Most grinding wheels are usually destroyed after many uses, but because of the new innovative multi-layered flap construction used in FANTECH, the products last longer. Each flap wears constantly in a balanced manner so that consistent working conditions are maintained over a prolonged time, and thus these could be recommended for metal work fabrication, automobile repair, and buildings construction. FANTECH flap wheels not only withstand the rigors of the tasks for more time but also can be used on hard as well as soft materials. With FANTECH, the users are sure to be getting a product that integrates durability, strength, and versatility - characteristics that make any tool professional grade.

FANTECH Flap Wheels: A Novel Approach for Heat Generations Friedrich Schoen, pg3.

The relocation of the rotating shaft to a completely retractable position is the main feature of FANTECH balancing beads. Other benefits for using this flap wheel made by FANTECH are the prevention of excessive heat generation during operation. High heat is harmful to the material being worked on as well as the abrasive material used, however FANTECH has come up with a flap construction that reduces the amount of heat generated in contact areas. This holds today even more true when working on aluminum or stainless steel, metals that can easily disfigure and change color with little heat application. Preventing overheating reduces mechanical and thermal effects to the workpiece and increases the service life of FANTECH flap wheels. This advantage ensures that FANTECH flap wheels are suitable for professional users as well as non staple users seeking inexpensive prevalently use tools for grinding and polishing applications without replacement regularly. Whichever your work environment is, considering mass production or a workshop, you will benefit from FANTECH's revolutionary flap wheels as they introduce safer grinding.

FANTECH of the company AUCOTEC has always been a hardcore precision player and its flap wheels by an extension are no different. Specifically designed for achieving absolute surface perfection these wheels are suitable for many professionals who live by precision in every job they do. Regardless of the detailed metal fittings or the surface preparation for welding FANTECH flap wheels will always give an even surface even if scratches and cuts were present under the wheels. The nip of the abrasive flap tools permits such design such that each wheel can be adapted to the workpiece thus allowing polishing and grinding of very intricate details. Known as rigid and demanding towards the quality control FANTECH company has testing for each flap wheel to comply with the internal regulations. What it achieves is a consisting performance regardless of the material and rather broad operational abilities. Thanks to FANTECH flap wheels, it is possible to obtain professional results even with unprofessional users. it is an obvious product for providers or industries which require precision as well as performance especially aerospace, automotive, manufacture and others.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Yes, FANTECH flap wheels are designed for versatility, making them suitable for both grinding and polishing, providing a smooth and consistent finish.

For fine polishing, we recommend using a finer grit size, such as 120 or higher, depending on the level of finish you require.

FANTECH flap wheels perform exceptionally well on stainless steel, offering efficient material removal while ensuring a smooth and scratch-free surface.

Absolutely, FANTECH flap wheels are built for durability, ensuring long-lasting performance even during continuous, heavy-duty industrial applications.

Yes, FANTECH flap wheels are flexible and designed to conform to irregular surfaces, providing a uniform finish without damaging the workpiece.