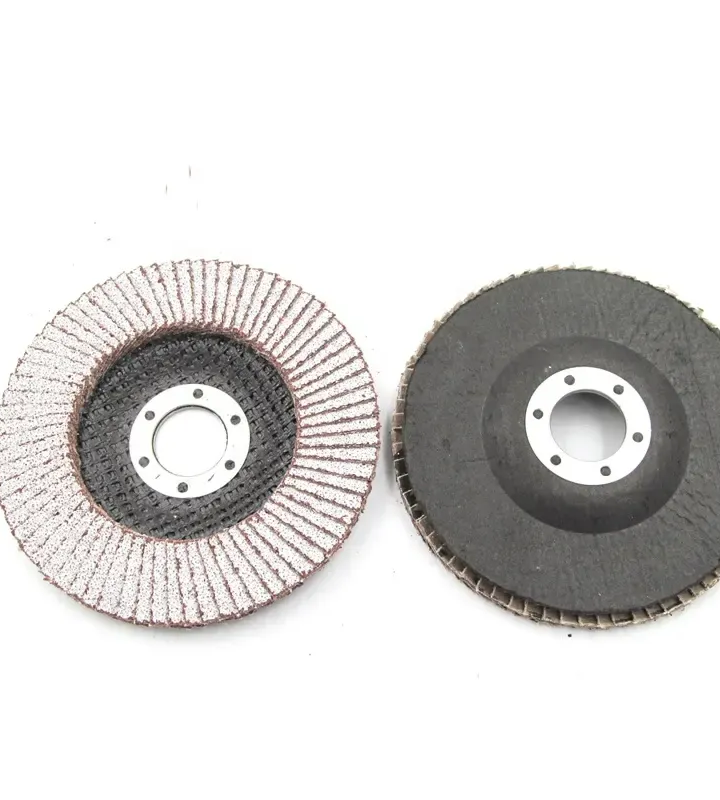

FANTECH Flap Wheel for All Types Of Metal Grinding Applications, Deburring, and Finishing

Coming from FANTECH is a flap wheel that is designed for heavy-duty metalworking applications such as grinding, deburring, and blending. The flaps consist of heavy-duty quality abrasive materials that longer and tougher cutting edges are available for stubborn metal parts. FANTECH’s flap wheel is different in a sense that it can also adapt to the contours of the workpiece which can be beneficial in complex fin processes where profiles are concerned. Wheel effectively cuts burrs and sharp edges and defects, and provides shiny smooth surface after use. For professionals dealing with the aerospace, automotive, or heavy machinery industries, flap wheel from FANTECH is a key solution for intricate finishing operations. Two points of FANTECH are worth noting – good aggressiveness with smooth cutting. FANTECH wheel grinds the workpiece without any damages/ gouges. Hence it is easy to keep the grinding work with high accuracy regardless of materials hardness level.

The flap wheels manufactured by FANTECH also demonstrate a high degree of accuracy over a given task. Whether surface preparation or metal grinding of a workpiece is concerned, FANTECH flap wheels continue to chop well with accuracy throughout use. Care is usually taken to appropriately design each flap to be worn out uniformly in such a way that, at the end of the job, a nice round and smooth wheel will be noticed. This is essential for people who work to tight tolerances and are called on to deliver precision and diving standards in their work. Thanks to the FANTECH brand’s commitment to quality control within the production process all the flap wheels have the same consistent quality of use regardless of the scope of work. From debarring metal parts to complicated shape components, FANTECH flap wheels are widely used by technicians and craftsmen that require a tool which can shoulder the burden of precision work. With FANTECH, the high quality and pleasing results obtained every time means that these flap wheels will be necessary to cut enhanced process time in every professional’s career.

FANTECH Flap Wheels: A Novel Approach for Heat Generations Friedrich Schoen, pg3.

The relocation of the rotating shaft to a completely retractable position is the main feature of FANTECH balancing beads. Other benefits for using this flap wheel made by FANTECH are the prevention of excessive heat generation during operation. High heat is harmful to the material being worked on as well as the abrasive material used, however FANTECH has come up with a flap construction that reduces the amount of heat generated in contact areas. This holds today even more true when working on aluminum or stainless steel, metals that can easily disfigure and change color with little heat application. Preventing overheating reduces mechanical and thermal effects to the workpiece and increases the service life of FANTECH flap wheels. This advantage ensures that FANTECH flap wheels are suitable for professional users as well as non staple users seeking inexpensive prevalently use tools for grinding and polishing applications without replacement regularly. Whichever your work environment is, considering mass production or a workshop, you will benefit from FANTECH's revolutionary flap wheels as they introduce safer grinding.

FANTECH: Flap wheels perfectly engineered for maximum efficacious stock removal

Each flap wheel design integrates efficiency as a consideration and FANTECH is no exception. This is because these are performed to the optimum making FANTECH flap wheels ideal to users who wish to work with speed and accuracy. FANTECH flap wheels are very aggressive in their intended use with respect to cutting hence surface preparation like rust, lacquer, and surface dirt removal is a quick task due to the abrasive proficiency. What makes all the difference for them is mainly the quality of the abrasive materials used and the flap arrangement design. Every wear of the wheel exposes a new shredding edge as each flap is covered down. There is high performance with this approach and it also minimizes the frequency of replacement of cut and worn out tools, therefore lowering the operational cost. Since FANTECH accommodates the provision of efficient and quality advantage tools, their flap wheels are suited for both the neglect activities of huge industries and also activities that require precision. If you need reliable results in a short time whether it is for surface preparation before painting or for running over welded joints, FANTECH flap wheels come through.

FANTECH of the company AUCOTEC has always been a hardcore precision player and its flap wheels by an extension are no different. Specifically designed for achieving absolute surface perfection these wheels are suitable for many professionals who live by precision in every job they do. Regardless of the detailed metal fittings or the surface preparation for welding FANTECH flap wheels will always give an even surface even if scratches and cuts were present under the wheels. The nip of the abrasive flap tools permits such design such that each wheel can be adapted to the workpiece thus allowing polishing and grinding of very intricate details. Known as rigid and demanding towards the quality control FANTECH company has testing for each flap wheel to comply with the internal regulations. What it achieves is a consisting performance regardless of the material and rather broad operational abilities. Thanks to FANTECH flap wheels, it is possible to obtain professional results even with unprofessional users. it is an obvious product for providers or industries which require precision as well as performance especially aerospace, automotive, manufacture and others.

QINGDAO FANTECH ABRASIVES CO., LTD, is a professional company in abrasives manufacture and export.

Our main products include cutting & grinding wheels, sanding rolls, sanding belts, resin fiber discs, flap discs, flap wheels, mini flap discs, quick-change discs, strip-it products, non-woven products, diamond product, and other abrasives accessories, etc. We offer OEM and ODM service. With our professional R&D team, we can manufacture different products according to customers' specific needs.

Built to withstand heavy use, ensuring longer life.

Durable design reduces the need for frequent replacements.

Ideal for irregular and contoured surfaces.

Provides excellent material removal with minimal effort.

Yes, FANTECH flap wheels are designed for versatility, making them suitable for both grinding and polishing, providing a smooth and consistent finish.

For fine polishing, we recommend using a finer grit size, such as 120 or higher, depending on the level of finish you require.

FANTECH flap wheels perform exceptionally well on stainless steel, offering efficient material removal while ensuring a smooth and scratch-free surface.

Absolutely, FANTECH flap wheels are built for durability, ensuring long-lasting performance even during continuous, heavy-duty industrial applications.

Yes, FANTECH flap wheels are flexible and designed to conform to irregular surfaces, providing a uniform finish without damaging the workpiece.